BIOREFINERY OF MICROALGAE: THE WORLD’S GREEN GEM FOR THE FUTURE SUSTAINABLE DEVELOPMENT

Article Highlights:

- Integrated biorefinery provides economic and environmental benefits

- Microalgae produce higher lipid content than plants

- Generally, microalgae produce higher carbohydrate contents essential for bioethanol

- Biohydrogen produced by microalgae is a future energy source

- As a biofertilizer, microalgae promotes plant growth

Abstract:

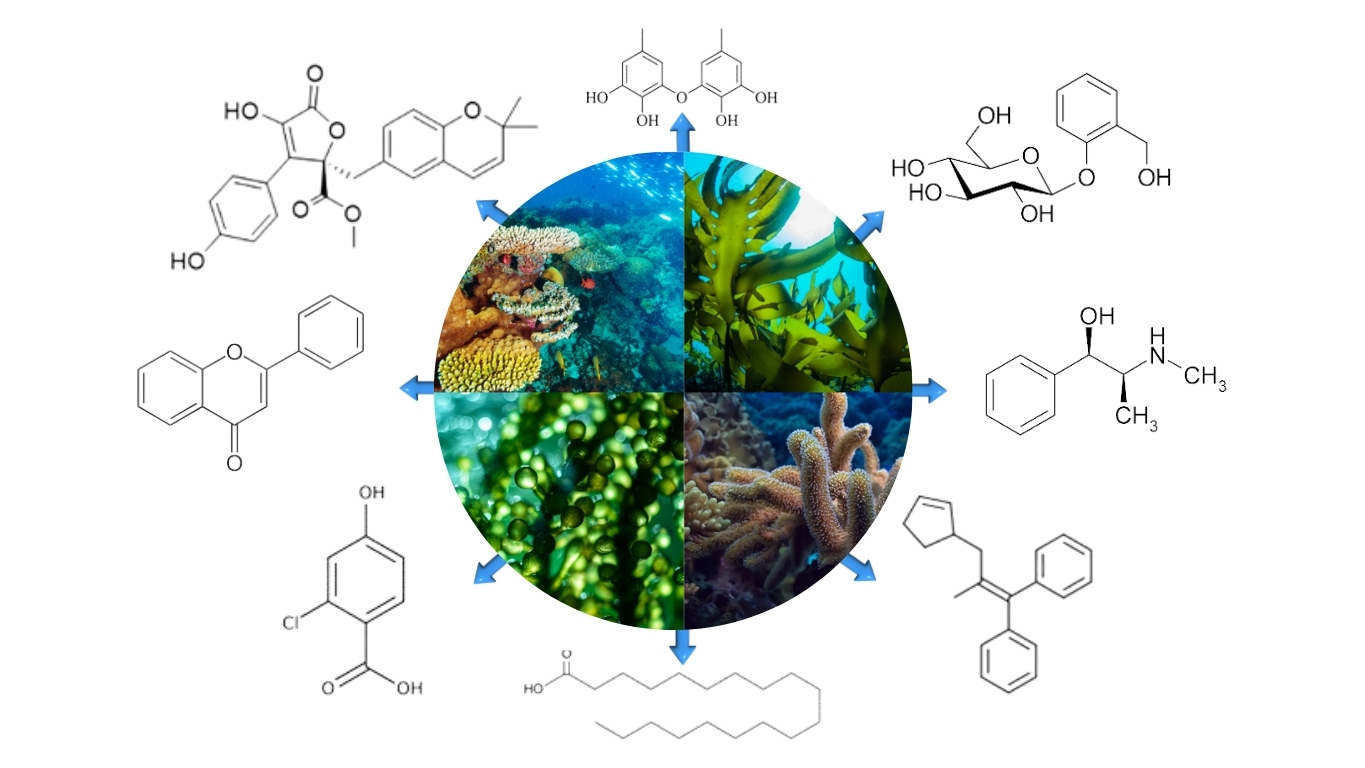

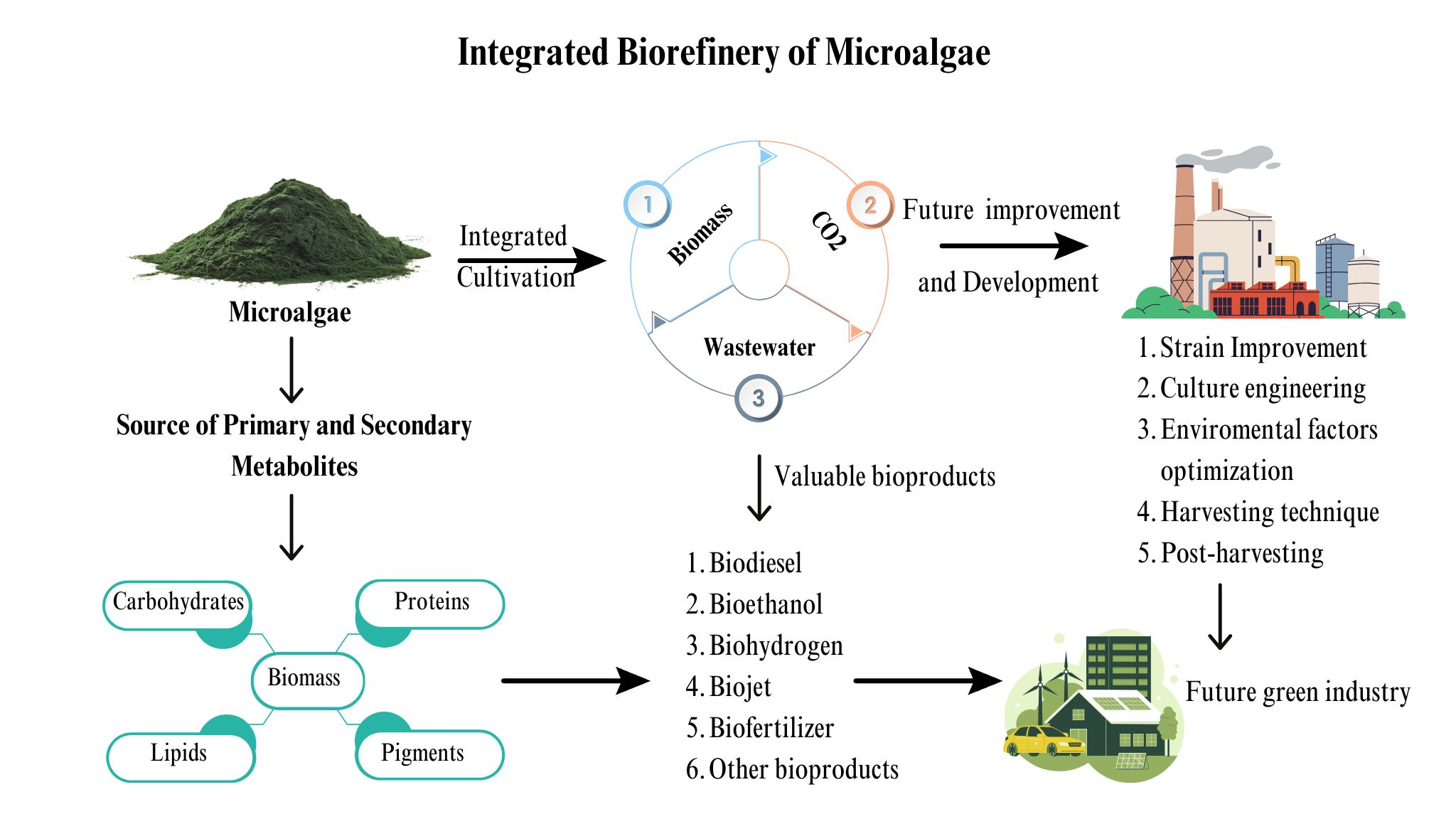

Industrial and household activities leading to many pollutants have been reduced by the presence of microalgae in the phycoremediation. Microalgae transform pollutants into many forms of biorefinery, such as biofuel, biojet, bioethanol, biohydrogen, and biofertilizer. The chemical residue resulted from household and industrial activities has abundant elements (N, P, C) for microalgal cell growth. The contents of a microalgal cell, like lipid and carbohydrates, depend on the nutrition in the medium, the cultivation system, the microorganism-mediator, and the applied technology. Chlorella vulgaris, Botryococcus braunii, Spirulina platensis, Chlorella sp., Chlamydomonas sp., and Chlorococcum sp., are potential lipid-producing microalgae and are applied in biofuel and biojet. The carbohydrate of Cyanobacteria synechoccus sp., Nannochloropsis oculata, and Arthospira platensis is the main content to be utilized in bioethanol. Meanwhile, for the application of biohydrogen, H2 gas is converted from Scenedesmus obliquus fermentation. However, the process of bioethanol and biohydrogen needs bacteria as a mediator of fermentation. Spirulina and Scenedesmus are examples of microalgae supporting soil fertility as biofertilizers. Extraction of microalgae can increase growth promotors for plants, like amino acids, peptides, and proteins, and also antibacterial and antifungal. Optimizing excellent microalgae content in bioenergy will face several challenges, for example, imbalances of organic waste. However, the phycoremediation of microalgae is a sustainable and futuristic solution to fulfill the need for energy stock.

Downloads

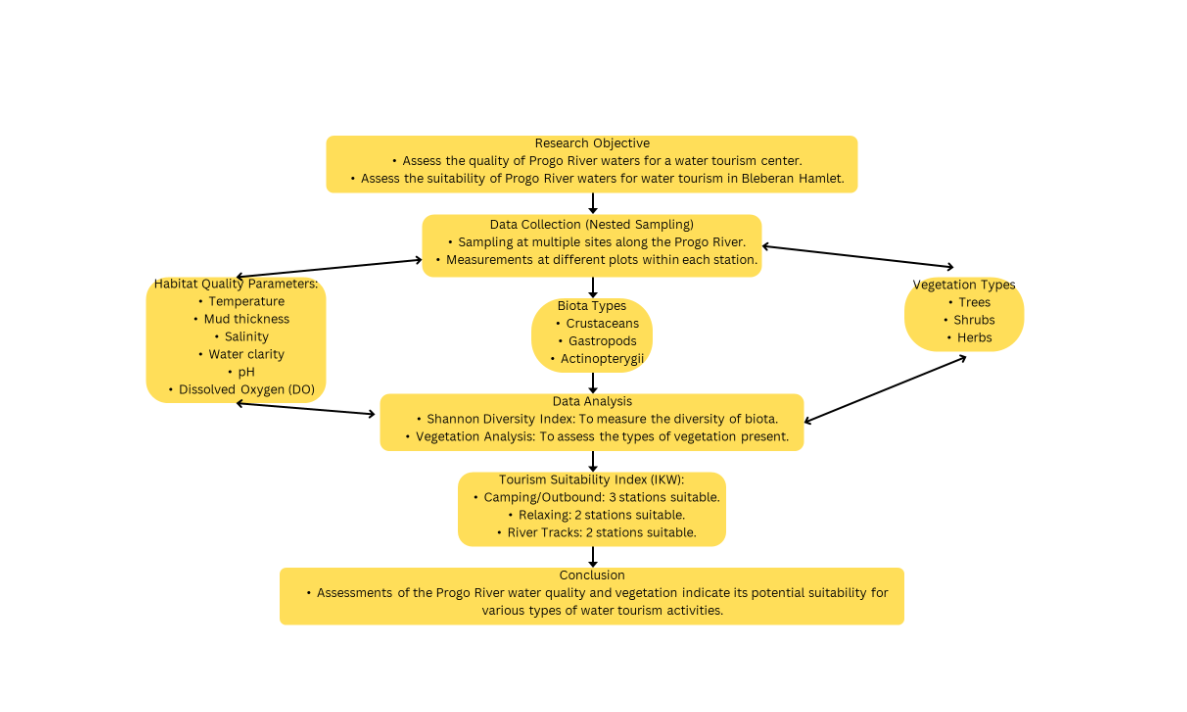

INTRODUCTION

The development aspect of a country, such as the economic aspect, tends to increase the consumption of fossil fuels to run factories, households, transportation, as well as to generate electricity and heat. Considering the excessive use of fossil fuels to support human activities, the supply of fossil fuels in the world will not be sufficient, while fossil fuel is also non-renewable. Additionally, the expansion of a country with a war also tends to add to the consumption of fossil fuels. In the future, climate or moderate warming around 2050 will increase energy demand predicted by 25 - 58%. Tropics and southern regions of the United States, Europe, and China will increase energy demand by more than 25%(Ruijven BJ et al., 2019). Although China is an Asian country that used the highest renewables for the production of energy in 2014, coal as a non-renewable source still be used within a quantity of 77%. The countries in Asia which depend on other non-renewable sources with their quantity are: Indonesia (70% coal), Japan (28% oil), and Malaysia (61% natural gas)(Sharvini et al., 2018).

The environmental impact caused by the usage of a non-renewable resource, especially carbon-based oil, has been a spotlight. To produce an eco-friendly profitable energy, microalgae, which is abundant in aquatic systems and other ecosystems, have been observed in many fields. Microalgae have been optimized into many forms, such as biohydrogen, bioethanol, biofuel, biojet, and other forms utilizing microalgae’s content, particularly lipid and carbohydrates.

Four algal strains, such as Chlorella vulgaris, Desmodesmus sp., Ettlia pseudoalveolaris, Scenedesmus obliquus, have been cultivated within a nitrogen-starving condition(Nzayisenga et al., 2020). This treatment triggered more lipid production which is a remarkable biodiesel in the form of triacyglycerols. Chlorella vulgaris is also optimized as a bioethanol that its quantity increases if fermentation time expands(Agwa et al., 2017). Microalgae-based oil which resulted from Chlorella sp. and Spirulina sp. was a result of conversion from triglycerides into fatty acid methyl ester and glycerol(, 2020). Many species of microalgae have been transformed into green energy. Therefore, this review aimed to describe the advantage of microalgae cultivation to support the application of future green-energy of the world.

REVIEW

Bioprospecting of Microalgae

Microalgae have been widely reported for having the ability to produce various commercial bioproducts, such as bioethanol, biofuel, biodiesel, biohydrogen, biojet, and biofertilizersTable 1. The relatively high lipid content makes microalgae a candidate for vital bioenergy feedstock in the future. Several strains that produce high amounts of lipid include Botryococcus, Nannochloropsis, and Chlorella sp. Carbohydrate content such as that found in Arthrospira platensis (60%)(Markou et al., 2013)and Chlamydomonas sp. (50%)(Kim et al., 2020)is also a critical source of bioethanol. Not only limited to the energy sector, microalgae can also be used as biofertilizers, such as those found in Schenedesmus obliquus(, 2019).

Some of the criteria for suitable microalgae strains to be used as candidates for lipid sources to produce biofuels are having a high growth rate, high lipid content, being able to grow in a variety of environmental conditions, including being resistant to contamination, being easily harvested, and being able to be processed using the latest lipid extraction method and potentially developed in many biorefinery activities(Resdi et al., 2016).

Two kinds of microalgae cultivation systems are commonly used, namely open pond and photobioreactor. Open pond is a microalgae cultivation system carried out openly(Egbo et al., 2018). An open microalgae cultivation system can be applied on a large scale. This system is suitable for wastewater treatment and is sustainable. There are several types of open pond cultivation systems, including shallow lagoons, ponds, inclined systems, circular ponds, mixed ponds, and raceway ponds(Borowitzka & Moheimani, 2013).

A photobioreactor is also called a closed system because it is carried out in a closed container made of translucent material(Egbo et al., 2018). Several types of photobioreactors are tubular reactors, flat plate reactors, pyramid reactors, fermenter types, and hybrid reactors. Tubular reactors consist of vertical tubular reactors, horizontal tubular reactors, helical tubular reactors, α-shaped reactors, and polyethylene bags and sleeves(Płaczek et al., 2017).

Photobioreactors require higher production costs than that of open ponds. However, the water demand in photobioreactor, the risk of contamination, as well as the loss of CO2and nutrient is lower compared to that in the open pond. A photobioreactor is made of translucent materials that can be penetrated by sunlight. Photobioreactor productivity is higher compared to that in open ponds. It is easier to regulate culture temperature in a photobioreactor than it is in an open pond. However, the commercialization of open ponds on a large scale has more potential(Egbo et al., 2018).

Phycoremediation can be used as a method of environmental recovery. Phycoremediation is safe, environmentally friendly, and relatively easy to perform. In addition, the microalgae biomass produced in this process can be used as a source of biodiesel production(Asiandu & Wahyudi, 2021). Bioprospecting of various algal species has resulted in many forms of bioenergy for utilizing the variation of growth-supporting chemical contentTable 1.

| No. | Algal Species | Bioprospect | Biochemical content or Roles | Ref. |

|---|---|---|---|---|

| 1. | Arthrospira platensis | Bioethanol and biodiesel | Carbohydrate content 60%, lipid < 10%, and protein > 20% | (Markou et al., 2013) |

| 2. | Botryococcus braunii | Biofuel | Lipid content 25 - 75% | (Chisti, 2007) |

Abdelaziz AEM, Leite GB, Hallenbeck PC. 2013. Addressing the challenges for sustainable production of algal biofuels: II. Harvesting and conversion to biofuels. Environ Technol 34(13–14):1807-36. DOI: 10.1080/09593330.2013.831487 DOI: https://doi.org/10.1080/09593330.2013.831487

Agwa OK, Nwosu IG, Abu GO. 2017. Bioethanol production from Chlorella vulgaris biomass cultivated with plantain Musa paradisiaca peels extract. Adv Biosci Biotechnol 08(12):478-90. DOI: 10.4236/abb.2017.812035 DOI: https://doi.org/10.4236/abb.2017.812035

Ahmad AL, Yasin NHM, Derek CJC, Lim JK. 2014. Comparison of harvesting methods for microalgae Chlorella sp. and its potential use as a biodiesel feedstock. Environ Technol 35(17):2244-53. DOI: 10.1080/09593330.2014.900117 DOI: https://doi.org/10.1080/09593330.2014.900117

Ahmad I, Abdullah N, Koji I, Yuzir A, Mohamad SE. 2021. Potential of microalgae in bioremediation of wastewater. Bull Chem React Eng Catal 16(2):413-29. DOI: 10.9767/bcrec.16.2.10616.413-429 DOI: https://doi.org/10.9767/bcrec.16.2.10616.413-429

Alavianghavanini A, Moheimani NR, Bahri PA. 2024. Process design and economic analysis for the production of microalgae from anaerobic digestates in open raceway ponds. Sci Total Environ 923(March):171554. DOI: 10.1016/j.scitotenv.2024.171554 DOI: https://doi.org/10.1016/j.scitotenv.2024.171554

Al-Jabri H, Das P, Khan S, Thaher M, Abdulquadir M. 2021. Treatment of wastewaters by microalgae and the potential applications of the produced biomass: A review. Water 13(27):1-26. DOI: 10.3390/w13010027 DOI: https://doi.org/10.3390/w13010027

Ashour M, Mansour AT, Alkhamis YA, Elshobary M. 2024. Usage of Chlorella and diverse microalgae for CO2 capture: Towards a bioenergy revolution. Front Bioeng Biotechnol 12(August):1-20. DOI: 10.3389/fbioe.2024.1387519 DOI: https://doi.org/10.3389/fbioe.2024.1387519

Asiandu AP, Wahyudi A. 2021. Phycoremediation: Heavy metals green-removal by microalgae and its application in biofuel production. J Environ Treat Tech 9(3):647-56. Available from: https://dormaj.org/index.php/jett/article/view/199

Barros AI, Gonçalves AL, Simões M, Pires JCM. 2015. Harvesting techniques applied to microalgae: A review. Renew Sustain Energy Rev 41:1489-1500. DOI: 10.1016/j.rser.2014.09.037 DOI: https://doi.org/10.1016/j.rser.2014.09.037

Batista AP, Moura P, Marques PASS, Ortigueira J, Alves L, Gouveia L. 2014. Scenedesmus obliquus as feedstock for biohydrogen production by Enterobacter aerogenes and Clostridium butyricum. Fuel 117(PART A):537-43. DOI: 10.1016/j.fuel.2013.09.077 DOI: https://doi.org/10.1016/j.fuel.2013.09.077

Borowitzka MA, Moheimani NR. 2013. Open pond culture system. In: Borowitzka MA, Moheimani NR (Editors). Algae for biofuels and energy. Dordrecht (NL): Springer. p.133-52). DOI: 10.1007/978-94-007-5479-9_8 DOI: https://doi.org/10.1007/978-94-007-5479-9_8

Branyikova I, Prochazkova G, Potocar T, Jezkova Z, Branyik T. 2018. Harvesting of microalgae by flocculation. Fermentation 4(4):1-12. DOI: 10.3390/fermentation4040093 DOI: https://doi.org/10.3390/fermentation4040093

Bwapwa J, Akash A, Trois C. 2018. Jet fuel from domestic wastewater treatment using microalgae: A review. In: Naushad Mu, Lichtfouse E (Editors). Green materials for wastewater treatment. Cham (CH): Springer Nature. p.321-60). DOI: 10.1007/978-3-030-17724-9_14 DOI: https://doi.org/10.1007/978-3-030-17724-9_14

Bwapwa J, Anandraj A, Trois C. 2018. Microalgae processing for jet fuel production. Biofuel Bioprod Biorefin (Biofpr) 12(4):522-35. DOI: 10.1002/bbb.1878 DOI: https://doi.org/10.1002/bbb.1878

Castro-Muñoz R, García-Depraect O. 2021. Membrane-based harvesting processes for microalgae and their valuable-related molecules: A review. Membranes 11(8):1-21. DOI:10.3390/membranes11080585 DOI: https://doi.org/10.3390/membranes11080585

Cheirsilp B, Srinuanpan S, Mandik YI. 2020. Efficient harvesting of microalgal biomass and direct conversion of microalgal lipid into biodiesel. In: Yousuf A (Editor). Microalgae cultivation for biofuels production. Cambridge (US): Elsevier. p.83-96). DOI:10.1016/B978-0-12-817536-1.00006-0 DOI: https://doi.org/10.1016/B978-0-12-817536-1.00006-0

Chen JT, Mustafa EM, Vello V, Lim P, Sulaiman NMN, Majid NA, …, Liew K. 2016. Preliminary assessment of Malaysian micro-algae strains for the production of bio jet fuel. IOP Conf Ser: Mater Sci Eng 152(1):1-7. DOI:10.1088/1757899X/152/1/012042 DOI: https://doi.org/10.1088/1757-899X/152/1/012042

Chisti Y. 2007. Biodiesel from microalgae. Biotechnol Adv 25(3):294-306. DOI:10.1016/j.biotechadv.2007.02.001 DOI: https://doi.org/10.1016/j.biotechadv.2007.02.001

Chisti Y. 2008. Biodiesel from microalgae beats bioethanol. Trend Biotechnol 26(3):126-31. DOI:10.1016/j.tibtech.2007.12.002 DOI: https://doi.org/10.1016/j.tibtech.2007.12.002

Culaba AB, Ubando AT, Ching PML, Chen WH, Chang JS. 2020. Biofuel from microalgae: Sustainable pathways. Sustainability 12(19):1-19. DOI:10.3390/su12198009 DOI: https://doi.org/10.3390/su12198009

Dineshkumar R, Rasheeq AA, Arumugam A, Nathiga Nambi K S, Sampathkumar P. 2019. Marine microalgal extracts on cultivable crops as a considerable bio-fertilizer: A review. Indian J Tradit Knowl 18(4):849-54.

Dineshkumar R, Subramanian J, Arumugam A, Rasheeq AA, Sampathkumar P. 2020. Exploring the microalgae biofertilizer effect on onion cultivation by field experiment. Waste Biomass Valori 11(1):77-87. DOI:10.1007/s12649-018-0466-8 DOI: https://doi.org/10.1007/s12649-018-0466-8

Dineshkumar R, Subramanian J, Gopalsamy J, Jayasingam P, Arumugam A, Kannadasan S, Sampathkumar P. 2017. The impact of using microalgae as biofertilizer in maize (Zea mays L.). Waste Biomass Valori 10(5):1101-10. DOI:10.1007/s12649-017-0123-7 DOI: https://doi.org/10.1007/s12649-017-0123-7

Egbo MK, Okoani AO, Okoh I. 2018. Photobioreactors for microalgae cultivation: An overview. Int J Sci Eng Res 9(11):65-74.

El-Shimi H, Attia N, El-Sheltawy S, El-Diwani G. 2013.Biodiesel production from Spirulina platensis microalgae by in situ transesterification process. J Sustain Bioenergy Syst 3:224-33. DOI:10.4236/jsbs.2013.33031 DOI: https://doi.org/10.4236/jsbs.2013.33031

Fattah IMR, Noraini MY, Mofijur M, Silitonga AS, Badruddin IA, Khan, TMY, …, Mahlia TMI. 2020. Lipid extraction maximization and enzymatic synthesis of biodiesel from microalgae. Appl Sci 10(17):6103. DOI:10.3390/app10176103 DOI: https://doi.org/10.3390/app10176103

Ferreira A, Ribeiro B, Ferreira A F, Tavares MLA, Vladic J, Vidović S., ..., Gouveia L. 2019. Scenedesmus obliquus microalga-based biorefinery – from brewery effluent to bioactive compounds, biofuels and biofertilizers – aiming at a circular bioeconomy. Biofuel Bioprod Biorefin (Biofpr) 13(5):1169-86. DOI:10.1002/bbb.2032 DOI: https://doi.org/10.1002/bbb.2032

Fetyan NAH, El-Sayed AEKB, Ibrahim FM, Attia YA, Sadik MW. 2021. Bioethanol production from defatted biomass of Nannochloropsis oculata microalgae grown under mixotrophic conditions. Environ Sci Pollut Res Int 29(2):2588-97. DOI:10.1007/s11356-021-15758-6 DOI: https://doi.org/10.1007/s11356-021-15758-6

Gonepalli TD, Oroszi TO. 2024. Integrating microalgae-based wastewater treatment for sustainable environmental and energy solutions: A review. World J Pharm Res 13(10):18-36. DOI: 10.20959/wjpr202410-32212

Gurreri L, Rindina MC, Luciano A, Falqui L, Fino D, Mancini G. 2024. Microalgae production in an industrial-scale photobioreactors plant: A comprehensive life cycle assessment. Sustain Chem Pharm 39:101598. DOI:10.1016/j.scp.2024.101598 DOI: https://doi.org/10.1016/j.scp.2024.101598

Kadam KL. 1997. Power plant flue gas as a source of CO2 for microalgae cultivation: Economic impact of different process options. Energy Convers Manag 38(SUPPL. 1):505-10. DOI:10.1016/s0196-8904(96)00318-4 DOI: https://doi.org/10.1016/S0196-8904(96)00318-4

Karthikeyan N, Prasanna R, Nain L, Kaushik BD. 2007. Evaluating the potential of plant growth promoting cyanobacteria as inoculants for wheat. Eur J Soil Biol 43(1):23-30. DOI:10.1016/j.ejsobi.2006.11.001 DOI: https://doi.org/10.1016/j.ejsobi.2006.11.001

Kawamura K, Hirano K, Ardianor A, Nugroho RA. 2020. The oil-producing microalga Botryococcus braunii: A method for isolation from the natural environment and perspectives on the role of ecological studies in algal biofuel production. J Ecosyst Ecogr 10(3):1-6.

Kim EJ, Kim S, Choi HG, Han S J. 2020. Co-production of biodiesel and bioethanol using psychrophilic microalga Chlamydomonas sp. KNM0029C isolated from Arctic sea ice. Biotechnol Biofuels 13(20):1-13. DOI:10.1186/s13068-020-1660-z DOI: https://doi.org/10.1186/s13068-020-1660-z

Kim JK, Um B, Kim TH. 2012. Bioethanol production from micro-algae, Schizocytrium sp., using hydrothermal treatment and biological conversion. Korean J Chem Eng 29(2):209-14. DOI:10.1007/s11814-011-0169-3 DOI: https://doi.org/10.1007/s11814-011-0169-3

Kucmanová A, Gerulová K. 2019. Microalgae harvesting: A review. Research Papers Faculty of Materials Science and Technology in Tranava Slovak University of Technology in Bratalislava 27(44):129-43. DOI:10.2478/rput-2019-0014 DOI: https://doi.org/10.2478/rput-2019-0014

Lakshmikandan M, Murugesan AG. 2016. Enhancement of growth and biohydrogen production potential of Chlorella vulgaris MSU-AGM 14 by utilizing seaweed aqueous extract of Valoniopsis pachynema. Renew Energy 96(Part A):390-99. DOI:10.1016/j.renene.2016.04.097 DOI: https://doi.org/10.1016/j.renene.2016.04.097

Lundquist TJ, Woertz IC, Quinn NWT, Benemann JR. 2010. A realistic technology and engineering assessment of algae biofuel production. Berkeley (US): Energy Biosciences Institute, University of California.

Margarites A, Costa J. 2014. Increment of carbohydrate concentration of minutissima microalgae for bioethanol production Chlorella. Int J Eng Res Appl 4(11):80-6.

Markou G, Angelidaki I, Nerantzis E, Georgakakis D. 2013. Bioethanol production by carbohydrate-enriched biomass of Arthrospira (Spirulina) platensis. Energies 6(8):3937-50. DOI:10.3390/en6083937 DOI: https://doi.org/10.3390/en6083937

Möllers KB, Cannella D, Jørgensen H, Frigaard NU. 2014. Cyanobacterial biomass as carbohydrate and nutrient feedstock for bioethanol production by yeast fermentation. Biotechnol Biofuels 7(64):1-11. DOI:10.1186/1754-6834-7-64 DOI: https://doi.org/10.1186/1754-6834-7-64

Mondal M, Goswami S, Ghosh A, Oinam G, Tiwari ON, Das P, …, Halder GN. 2017. Production of biodiesel from microalgae through biological carbon capture: A review. 3 Biotech 7(2):1-21. DOI:10.1007/s13205-017-0727-4 DOI: https://doi.org/10.1007/s13205-017-0727-4

Nagaraja YP, Biradar C, Manasa KS, Venkatesh HS. 2014. Production of biofuel by using micro algae (Botryococcus braunii). Int J Curr Microbiol Appl Sci 3(4):851-60.

Nayak M, Swain DK, Sen R. 2019. Strategic valorization of de-oiled microalgal biomass waste as biofertilizer for sustainable and improved agriculture of rice (Oryza sativa L.)crop. Sci Total Environ 682:475-84. DOI:10.1016/j.scitotenv.2019.05.123 DOI: https://doi.org/10.1016/j.scitotenv.2019.05.123

Novoveska L, Nielsen SL, Eroldoğan TO, Haznedaroglu BZ, Rinkevich B, Fazi S, …, Vasquez M. 2023. Overview and challenges of large-scale cultivation of microalgae and cyanobacteria . Marine Drugs 21(8):445. DOI:10.3390/md21080445 DOI: https://doi.org/10.3390/md21080445

Nzayisenga JC, Farge X, Groll SL, Sellstedt A. 2020. Effects of light intensity on growth and lipid production in microalgae grown in wastewater. Biotechnol Biofuels 13(1):1-8. DOI:10.1186/s13068-019-1646-x DOI: https://doi.org/10.1186/s13068-019-1646-x

Onay M. 2018. Bioethanol production from Nannochloropsis gaditana in municipal wastewater. Energy Procedia 153:253-57. DOI:10.1016/j.egypro.2018.10.032 DOI: https://doi.org/10.1016/j.egypro.2018.10.032

Oostlander PC, van Houcke J, Wijffels R H, Barbosa MJ. 2020. Microalgae production cost in aquaculture hatcheries. Aquaculture 525:735310. DOI:10.1016/j.aquaculture.2020.735310 DOI: https://doi.org/10.1016/j.aquaculture.2020.735310

Phang SM, Mustafa E, Ambati R, Sulaima N, Lim P-E, Majid N, …, Liew K-E. 2015. Checklist of microalgae collected from different habitats in Peninsular Malaysia for selection of algal biofuel feed-stocks. Malaysian J Sci 34(2):141-67. DOI:10.22452/mjs.vol34no2.2 DOI: https://doi.org/10.22452/mjs.vol34no2.2

Płaczek M, Patyna A, Witczak S. 2017. Technical evaluation of photobioreactors for microalgae cultivation. E3S Web of Conferences 19:1–10. DOI:10.1051/e3sconf/20171902032 DOI: https://doi.org/10.1051/e3sconf/20171902032

Pradana YS, Dewi RN, Livia KD, Arisa F, Rochmadi, Cahyono RB, Budiman A. 2020. Advancing biodiesel production from microalgae Spirulina sp. by a simultaneous extraction-transesterification process using palm oil as a co-solvent of methanol. Open Chemistry 18(1):833-42. DOI:10.1515/chem-2020-0133 DOI: https://doi.org/10.1515/chem-2020-0133

Qu W, Loke P, Hasunuma T, Ho SH. 2020. Optimizing real swine wastewater treatment efficiency and carbohydrate productivity of newly microalga Chlamydomonas sp. QWY37 used for cell-displayed bioethanol production. Bioresour Technol 305:1-9. DOI:10.1016/j.biortech.2020.123072 DOI: https://doi.org/10.1016/j.biortech.2020.123072

Rahman A, Prihantini NB, Nasruddin. 2019. Fatty acid of microalgae as a potential feedstock for biodiesel production in Indonesia. AIP Conf Proc 2062:020059. DOI:10.1063/1.5086606 DOI: https://doi.org/10.1063/1.5086606

Rajvanshi S, Sharma MP. 2012. Micro algae: A potential source of biodiesel. J Sustain Bioenergy Syst 02(03):49-59. DOI:10.4236/jsbs.2012.23008 DOI: https://doi.org/10.4236/jsbs.2012.23008

Resdi R, Lim JS, Kamyab H, Le, CT, Hashim H, Mohamad N, Ho WS. 2016. Review of microalgae growth in palm oil mill effluent for lipid production. Clean Technol Envir 18(8):2347-61. DOI:10.1007/s10098-016-1204-1 DOI: https://doi.org/10.1007/s10098-016-1204-1

Rinanti A, Fachrul MF, Hadisoebroto R, Desty S, Rahmadhania R, Widyaningrum DA, Saad NA. 2021. Heavy metal pollutant sorption in aquatic environment by microalgae consortium. Indonesian Journal of Urban and Environmental Technology 5(1):51-71. DOI:10.25105/urbanenvirotech.v5i1.10747 DOI: https://doi.org/10.25105/urbanenvirotech.v5i1.10747

Rushan NH, Yasin NHM, Sepian NRA, Said FM, Shafei NI. 2019. Effect of immobilization method on the growth of Chlorella vulgaris and fatty acid profile for biodiesel production. Indones J Chem 19(3):767-76. DOI:10.22146/ijc.39800 DOI: https://doi.org/10.22146/ijc.39800

Santoso AD, Hariyanti J, Pinardi D, Kusretuwardani K, Widyastuti N, Djarot IN, …, Apriyanto H. 2023. Sustainability index analysis of microalgae cultivation from biorefinery palm oil mill effluent. Glob J Environ Sci Manag 9(3):559-76. DOI:10.22035/gjesm.2023.03.13

Schade S, Meier T. 2021. Techno-economic assessment of microalgae cultivation in a tubular photobioreactor for food in a humid continental climate. Clean Technol Envir 23(5):1475-92. DOI:10.1007/s10098-021-02042-x DOI: https://doi.org/10.1007/s10098-021-02042-x

Sharvini SR, Noor ZZ, Chong CS, Stringer LC, Yusuf RO. 2018. Energy consumption trends and their linkages with renewable energy policies in East and Southeast Asian countries: Challenges and opportunities. Susta Environ Res 28(6):257-66. DOI:10.1016/j.serj.2018.08.006 DOI: https://doi.org/10.1016/j.serj.2018.08.006

Show LP. 2022. Global market and economic analysis of microalgae technology: Status and perspectives. Bioresour Technol 357(April):127329. DOI:10.1016/j.biortech.2022.127329 DOI: https://doi.org/10.1016/j.biortech.2022.127329

Singh G, Patidar SK. 2018. Microalgae harvesting techniques : A review. J Environ Manag 217: 499-508. DOI:10.1016/j.jenvman.2018.04.010 DOI: https://doi.org/10.1016/j.jenvman.2018.04.010

Sommer U, Stibor H, Katechakis A, Sommer F, Hansen T. 2002. Pelagic food web configurations at different levels of nutrient richness and their implications for the ratio fish production. Hydrobiologia 484:11-20. DOI:10.1023/A:1021340601986. DOI: https://doi.org/10.1007/978-94-017-3190-4_2

Song W, Rashid N, Choi W, Lee K. 2011. Biohydrogen production by immobilized Chlorella sp. using cycles of oxygenic photosynthesis and anaerobiosis. Bioresour Technol 102(18):8676-81. DOI:10.1016/j.biortech.2011.02.082 DOI: https://doi.org/10.1016/j.biortech.2011.02.082

Tourang M, Baghdadi M, Torang A, Sarkhosh S. 2019. Optimization of carbohydrate productivity of Spirulina microalgae as a potential feedstock for bioethanol production. Int J Environ Sci Technol 16(3):1303-18. DOI:10.1007/s13762-017-1592-8 DOI: https://doi.org/10.1007/s13762-017-1592-8

van Ruijven BJ, De Cian E, Wing IS. 2019.Amplification of future energy demand growth due to climate change. Nat Commun 10(1):1–12. DOI:10.1038/s41467-019-10399-3 DOI: https://doi.org/10.1038/s41467-019-10399-3

Velásquez-Orta SB, Yáñez-Noguez I, Ramírez IM, Ledesma MTO. 2024. Pilot-scale microalgae cultivation and wastewater treatment using high-rate ponds: a meta-analysis. Environ Sci Pollut Res 31(34):46994-47021. DOI:10.1007/s11356-024-34000-7 DOI: https://doi.org/10.1007/s11356-024-34000-7

Widjaja A. 2009. Lipid production from microalgae as a promising candidate for biodiesel production. MAKARA of Technol Ser 13(1):47-51. DOI:10.7454/mst.v13i1.496 DOI: https://doi.org/10.7454/mst.v13i1.496

Zhang Y, Li Y, Zhang X, Tan T. 2015. Biodiesel production by direct transesterification of microalgal biomass with co-solvent. Bioresour Technol 196:1-4. DOI:10.1016/j.biortech.2015.07.052 DOI: https://doi.org/10.1016/j.biortech.2015.07.052

Copyright (c) 2025 Angga Puja Asiandu, Widya Sari, Ahmad Saefun Naser, Wulan Rahmani Akmal, Dedy Setyawan, Dita Aulia Yulyanita

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish with this journal agree with the following terms:

- Authors retain copyright and grant the journal right of first publication, with the work 1 year after publication simultaneously licensed under a Creative Commons attribution-noncommerical-noderivates 4.0 International License that allows others to share, copy and redistribute the work in any medium or format, but only where the use is for non-commercial purposes and an acknowledgement of the work's authorship and initial publication in this journal is mentioned.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgement of its initial publication in this journal.

- Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See The Effect of Open Access).